robwright

New member

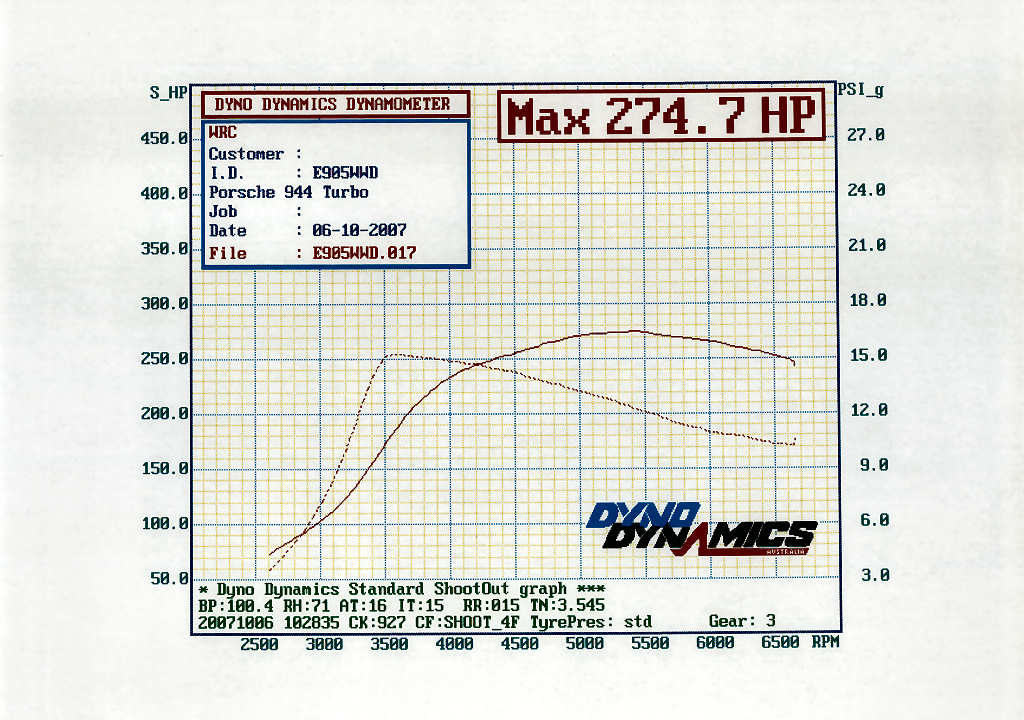

Guys I mentioned this briefly on another thread but didn't want to hijack it. I have just got into analysing my AFRs recently so I can get to know the car more with a view to what I can do in the future. I am a bit concerned about my WOT AFR. I have set my idle AFR at 14.2, which equates to 0.6% CO and my cruising AFRs are around 14.7 at 40 mph and 14.2 at 80 mph. When on power but not on WOT at low to middle revs my AFR is in the low 12s. All good so far. However when I floor it and start reaching the higher revs my AFR is dipping below 11 to the 10.5s -10.9s. This of course puts me at risk of borewash due to the amount of fuel being delivered. The car is running 18 psi on a very new K26/6 turbo and standard injectors. I have a Tial DPW and 3 bar FPR. The chips are max 951 chips from Russel Berry who chips for Lynsey Racing. These were arranged by Vic Timpauer of Pauer Tuning, from whom I bought the Tial. So my question to the rest of you tuning guys is short of a custom map from the dyno what other options do I have? I have considered fitting a K&N panel filter to try and increase the air volume into the engine but I am not convinced that this is the answer. All help will be gratefully received as always guys.