Hi,

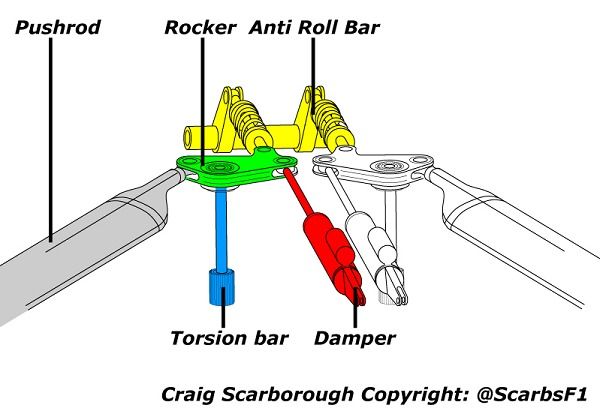

The driver side front anti-roll bar drop link has snapped on my 1986 turbo. I intend to replace this myself, can anyone give guidance on the method regarding taking up the tension on the ARB? I guess a scissor jack might be needed to force up the ARB?

Can the drop link be accessed by removing the wheel, or does the car need to go up on ramps?

On PET the diagram shows two designs for the drop link, one which is a pressed steel L shaped plate with a steel loop that goes around the bush, and the other design is a threaded bar with the loop welded onto the end. Its the pressed steel type that failed on my car. Does anyone know why two different designs are shown on PET?

thank you in anticipation.

The driver side front anti-roll bar drop link has snapped on my 1986 turbo. I intend to replace this myself, can anyone give guidance on the method regarding taking up the tension on the ARB? I guess a scissor jack might be needed to force up the ARB?

Can the drop link be accessed by removing the wheel, or does the car need to go up on ramps?

On PET the diagram shows two designs for the drop link, one which is a pressed steel L shaped plate with a steel loop that goes around the bush, and the other design is a threaded bar with the loop welded onto the end. Its the pressed steel type that failed on my car. Does anyone know why two different designs are shown on PET?

thank you in anticipation.