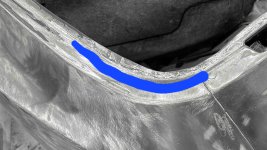

How bad is it, my passengers side had failed here, there was little of the lip left. I was thinking of getting a new lip fabricated until the old bodyshop that replaced the area in front of the wheels informed me that they still had the rest of the rear qtr that I had bought new from Porsche more than 15 years ago, lucky me. You can see some pictures of this section now stitched onto the car on page 29 of my thread.

Looking at your suggestions, I don't think drilling a hole is a good idea as this lip is where the qtr is welded to the inner section. Having said that, a hole with a small steel tube welded into it might work but you need to be sure that its a good weld with no chance of water seeping through the weld into the battery housing area.

Don't think you'll be happy in filling the channel, plus it would be noticeable if ever selling.

Same goes for folding the lip, easily spotted.

Leaving it really depends on my first question, how bad is it?

If not too bad, an alternative could be to clean the area up, use something like POR15 ( available from Frost Restorations) to kill the rust and give a solid ceramic based coating. I used this on my inner sill when my son welded in a new section without removing the outer sill.

In the same series of photos in my thread, you can see this section when they removed the outer sill for replacement this time around. Note that it's not welded at the front end as all the welding was done from underneath, my point is that the metal still looks as good as when fitted 7 years ago, the sill itself still looks fairly good too and I had be told they could patch up the tiny hole but I played safe and chose a new sill.

Pete