peanut

Active member

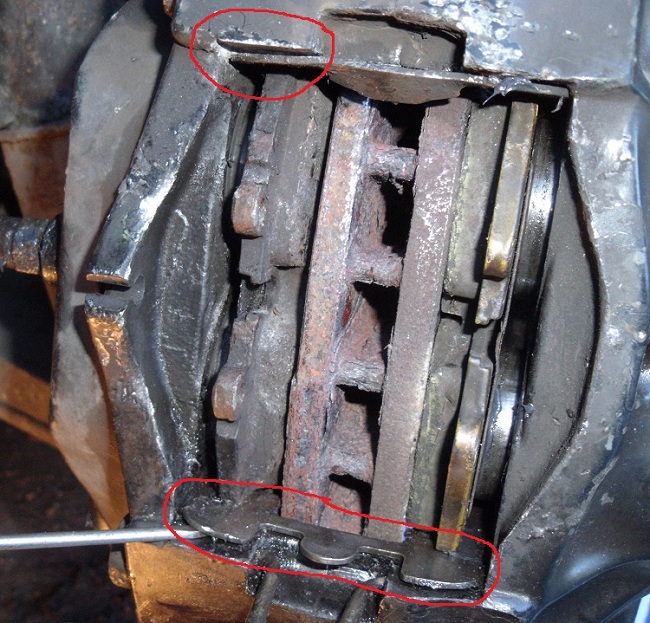

I thought any members that were unfamiliar with this phenomena might be interested to see the result of 'plate lift'

One of the front brake pads became stuck some time last year and eventually only about 1/3rd of the pad was contacting the rear of the brake disc. its possible that due to the rear of the disc being completely covered by a metal sheild it may have escaped the notice of the last MOT test inspector.

I didn't notice any significant reduction in braking efficiency but I rarely if ever need to do an urgent or emergecy stop.

Interestingly enough recent changes in the MOT test means that even discs in this appalling state cannot be failed providing the overall braking efficiency measured, is according to the current standard ! This disc passed the MOT just 2x weeks ago !

Aluminium brake calipers have stainless steel plates fitted top and bottom to protect the relatively soft aluminium from the edges of the steel brake pads. Over time the heat and build up of fine dust and road grit gets under the SS plates and the resultant oxidation causes further plate lift which allows more crap to get under the plates.

Eventually the brake pads start to jam between the 2x SS plates and do not retract adequately. This causes dust and muck to build up on the caliper pistons due to the lack of normal self cleaning movement of the pistons . This can eventually lead to pitting of the piston surfaces as the pistons jam.

Its very important when replacing brake pads to make sure that the brake pads can move freely through the full range of the caliper pistons as the pads wear in normal use. If you need to tap, hammer or prise the pads in or out of the caliper then its essential that they are eased preferably by fitting new SS plates and refurbishing the calipers. As a temporary measure the top and bottom edges of the brake pads can be filed carefully until they move freely and the plates cleaned thoroughly .

Hope this is of interest to anyone who hasn't tackled their brakes yet

One of the front brake pads became stuck some time last year and eventually only about 1/3rd of the pad was contacting the rear of the brake disc. its possible that due to the rear of the disc being completely covered by a metal sheild it may have escaped the notice of the last MOT test inspector.

I didn't notice any significant reduction in braking efficiency but I rarely if ever need to do an urgent or emergecy stop.

Interestingly enough recent changes in the MOT test means that even discs in this appalling state cannot be failed providing the overall braking efficiency measured, is according to the current standard ! This disc passed the MOT just 2x weeks ago !

Aluminium brake calipers have stainless steel plates fitted top and bottom to protect the relatively soft aluminium from the edges of the steel brake pads. Over time the heat and build up of fine dust and road grit gets under the SS plates and the resultant oxidation causes further plate lift which allows more crap to get under the plates.

Eventually the brake pads start to jam between the 2x SS plates and do not retract adequately. This causes dust and muck to build up on the caliper pistons due to the lack of normal self cleaning movement of the pistons . This can eventually lead to pitting of the piston surfaces as the pistons jam.

Its very important when replacing brake pads to make sure that the brake pads can move freely through the full range of the caliper pistons as the pads wear in normal use. If you need to tap, hammer or prise the pads in or out of the caliper then its essential that they are eased preferably by fitting new SS plates and refurbishing the calipers. As a temporary measure the top and bottom edges of the brake pads can be filed carefully until they move freely and the plates cleaned thoroughly .

Hope this is of interest to anyone who hasn't tackled their brakes yet