ORIGINAL: sawood12

ORIGINAL: TTM

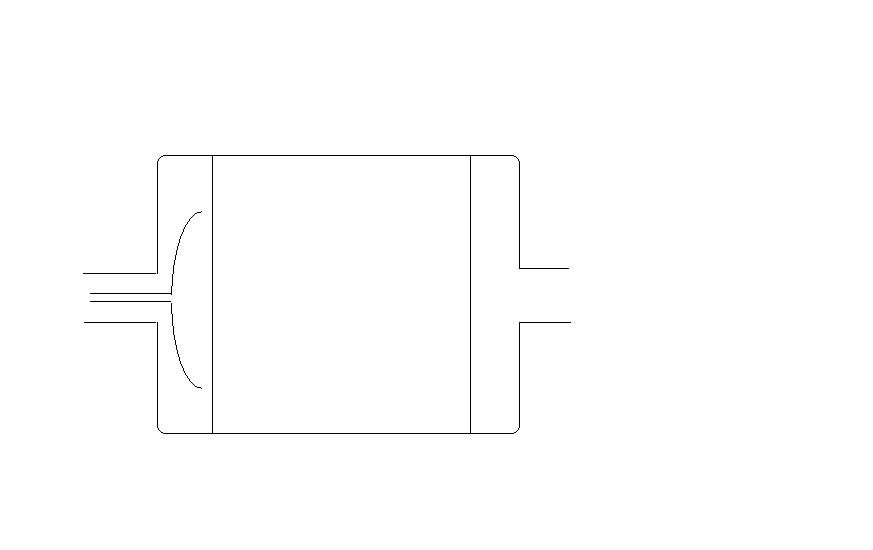

The original intake manifold "works" with a 2.7 head if its round ports are ovally widened to fit, but to me such a modification somewhat feels like a band-aid - as far as I understand Fluid Mechanics the velocity of air will decrease in the runners of the intake manifold as the section gradually turns from round to oval (the oval section being larger than the round one), well at least if the pre intake valve air pressure remains constant.

Thoughts? [8|]

It is cross sectional area that is important. If the shape changes as the cross sectional area remains the same then you will get no difference in velocity or pressure (apart from usual losses due to boundry layers and eddy's) assuming that the shape change is gradual and not severe. If you reduce cross sectional area the velocity will increase and the pressure will decrease and visa versa in the case of the cross sectional area increasing.

However this is all largely irrelevant to intake manifolds as you don't have constant and steady flow. You have a pulsing flow with the air inside the manifold changing direction and exhibiting pressure waves within the runners as the valves open and close. This makes things much more complicated by a significant magnitude. The location of these pressure waves along the length of the runners will vary depending upon engine RPM and load. So a single fixed manifold design is a compromise that will only really work for one specific set of parameters of RMP and load and outside of that sweet spot the manifold design will not be optimised. That is why things like VarioRam exists as it attempts to change the properties of the manifold to widen the manifolds operational 'sweet spot'. VarioRam changes the volume of the manifold plenum (the bit that opens up and feeds the runners) to try to dampen out these pulses and to keep the position of the pressure waves constant over a wider RPM band. Conventional design aims to position the pressure waves such that you have an area of high pressure at the cylinder head port to maximise the filling of the cylinder. The downside is that high pressure = higher temperature, but the design is such the benefits outweigh the downsides.

This is why flow bench figures are largely irrelevant. You can have two manifolds of different designs and the one that flows the least might actually be the better option for the given application.

It is rare that the intake manifold is the biggest restriction in an engine anyway. As DevineE says, the IC and other downstream components will present larger restrictions.

The shape of the port is chosen to influence turbulence as the air enters the cylinder through the port. In a turbocharged car then this is of lesser importance under boost at least due to the pressure the air is less inclined to be turbulent and any turbulence settles much quicker. For an N/A car oval ports are more likely to be utilised to minimise turbulence as turbulence causes the velocity of the air (in random directions though) to increase, pressure to decrease, energy taken out of the airflow, losses and ultimately less air to getting into the cylinder. However turbulence is good for fuel mixing - so as always there is a classic Engineering paradox - the two main things you are trying to achieve are diametrically opposing. This is why there is no such thing as one single 'best' design. It all depends upon what you're after, so by saying "such and such's car's manifold runners are tool short or long" is not really relevant as they may be like that on purpose to achieve a specific aim.

Complicated stuff and to simply say one engine is better than another because it develops more power or torque is shortsighted and is like viewing a potential house purchase by simply looking through the letterbox.